INTRODUCE :

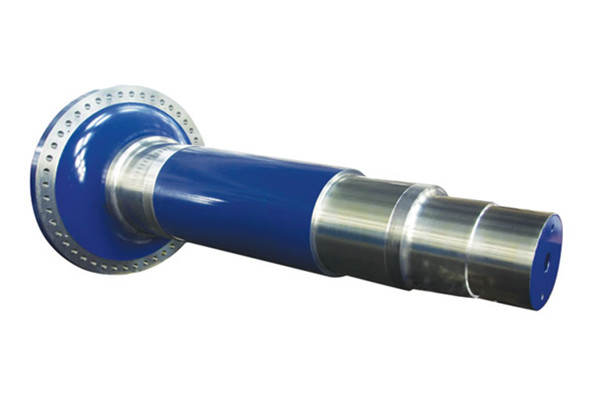

Kingrail Parts manufactures forged industrial crankshafts of various sizes for heavy equipment. After more than 20 years of development, we can provide forged crankshafts for mining, non-ferrous metals, chemicals, metallurgy, building materials, environmental protection, and large machinery.

We use the highest quality materials to customize forged crankshafts. As a leading forged crankshaft manufacturer, our forging experts can help you determine the material that best suits your needs.

SPECIFICATIONS :

Technical parameters

|

Product Name |

Large Crankshaft |

|

Model |

According to customer requirement |

|

Material |

Cast iron or forged steel |

|

Stroke |

Standard |

|

Main Journal |

Standard |

|

Warranty |

12 months |

|

MOQ |

We accept small order, different products have different MOQ |

|

Supply Ability |

10000 pcs/month |

|

Delivery Time |

About 30 days after received payment |

Production capacity of shaft products

Length 5000mm, rotation diameter 730mm, medium and high speed diesel engine crankshaft processing;

Length 5000mm, rotation diameter 1250mm, shaft parts processing;

Length 2100mm, rotation diameter 200mm, camshaft and special-shaped rotating parts processing;

Length 1500mm, rotation diameter 200mm concave camshaft processing;

Length 1000mm, inner hole diameter 200mm, various medium and high speed diesel engine connecting rod processing.

Our forged crankshaft products are sold well in Asia, Africa, Europe, Australia and other countries and regions, and occupy a high market share at home and abroad.

Why Choose Us

1. Expertise: Decades of experience in forging industrial components

2. Customization: We can also provide forged industrial crankshafts based on your drawings to meet your exact machinery needs

4. Quality: High-strength forged components carefully crafted from the best materials

5. Fast Turnaround: We offer the fastest turnaround time in the industry

Get More Help

Please contact us for more information and a quote.