INTRODUCE :

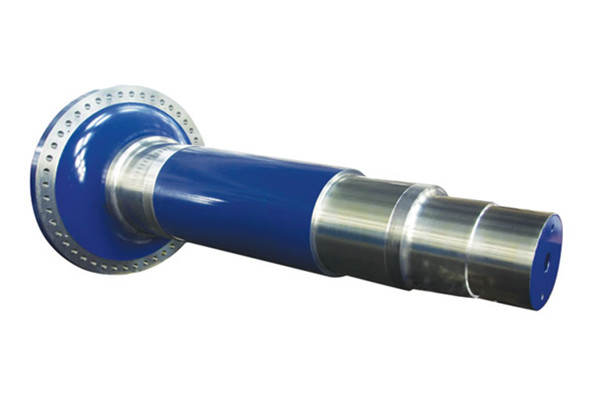

Kingrail Parts produces forged steel and stainless steel rotor shafts that guarantee sound center in all shapes and sizes, including round, square, rectangular, polygonal, concentric or eccentric configurations and custom shapes.

Forged Rotor Shaft Applications

* Turbines

* Pumps

* Compressors

* Drills

* Fans

* Generators

* Conveyors

* Construction Equipment

SPECIFICATIONS :

Forging Method: Free Forging/Free Forging

Material: Alloy Steel, Carbon Steel, Stainless Steel

Specifications: Maximum Weight: 80 tons for forgings, 120 tons for ingots

Maximum Length: 12 meters after heat treatment, 20 meters for forgings

Production Process

Ingot Purchase---Chemical Composition Test---Heating---Forging---UT and Dimension Test---Normalizing and Tempering, Proofing Processing---UT and Dimension Test---Sampling---Mechanical Property Test---Quenching and Tempering---Secondary Processing---UT and Dimension Test---Final Processing—MT and Dimension, Surface Test.

UT Test

100% ultrasonic test according to EN10228, ASTM388, September 1921 C/c, etc.

Factory Report

EN10204 3.1-----Chemical composition, mechanical properties, UT and MT, heat treatment report, dimensions, etc.

Inspection

Factory self-weight or by third party

Standard

ASTM, GB, DIN, BS, JIS, etc.

Get more help

Please contact us for more information and quotation.