INTRODUCE :

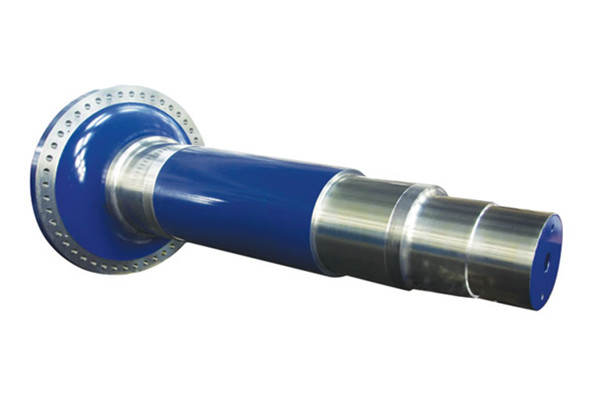

4340 alloy steel axle forged rough machined square drive shaft

SPECIFICATIONS :

Delivery contents

|

Item No |

Quantity(Pcs) |

Description |

Heat No |

Factory Product No |

|

Forged square shaft |

3 |

square 230*3886 |

20170408-210 |

4775-4777 |

Chemical Analysis

|

Heat No |

C% |

Si% |

Mn% |

S% |

Cr % |

Mo % |

Ni% |

P% |

H% |

|

4340 |

0.38-0.43 |

0.10-0.35 |

0.60-0.80 |

S:0.008-0.016 |

0.70-0.90 |

0.20-0.30 |

1.65-2.0 |

P≤0.015 |

H≤2.0 |

|

1703B033 |

0.42 |

0.23 |

0.68 |

0.008 |

0.83 |

0.27 |

1.78 |

0.014 |

1.2 |

Mechanical Tests

|

Specimen |

Test Temp |

Yield Strength |

Tensile Strength |

Elongation(Tr) |

Reduction of Area |

Charpy Impact(20℃) |

Hardness |

|

|

Nr./No |

20℃ |

Rp0.2 N/mm² |

Rm N/mm² |

A% |

Ψ% |

Joule |

HB |

|

|

4340 |

|

|

|

|

L |

T |

|

|

|

YL4775 |

|

|

|

|

|

|

350-355 |

|

|

YL4776 |

|

|

|

|

|

|

355-365 |

|

|

YL4777 |

|

|

|

|

|

|

350-357 |

|

Metallographic Test Report

|

Sample Name |

Forged Shaft |

Item No: |

00055928 |

Factory Product No |

YL4775-YL4777 |

||||

|

-YLQuantity( Pcs) |

3 |

Material |

4340 |

Heat No |

20170408-210 |

||||

|

Sample Condition |

OK |

Heat treatment |

Q+T |

Test Place |

Laboratory |

||||

|

Ambient Condition |

23℃ |

Test Date |

|

Sampling Location |

Longitudinal |

||||

|

Test Standard |

ASTM E45-76 Method A |

||||||||

|

Test Results |

|||||||||

|

|

Test Item |

|

Technical Requirements |

Test Results |

Single Evaluation |

||||

|

Non-Metallic Inclusions |

Type A |

Thin |

≤1.5 |

|

Qualified |

||||

|

|

Thick |

≤1.5 |

|

Qualified |

|||||

|

Type B |

Thin |

≤1.5 |

|

Qualified |

|||||

|

|

Thick |

≤1.5 |

|

Qualified |

|||||

|

Type C |

Thin |

≤1.5 |

|

Qualified |

|||||

|

|

Thick |

≤1.5 |

|

Qualified |

|||||

|

Type D |

Thin |

≤1.5 |

|

Qualified |

|||||

|

|

|

Thick |

≤1.5 |

|

Qualified |

||||

|

Grain size |

≥6 |

|

Qualified |

||||||

|

Statement:This report only responsible for samples |

|||||||||

Ultrasonic Test Certificate

|

Parts |

Customer |

|

Date |

2017-04-19 |

|||

|

Name of forging |

Forged shaft |

Testing surface |

Surface |

||||

|

Material of forging |

4340 |

Surface condition |

Ra 6.3 μm |

||||

|

Test Condition Requirement |

Woke piece state |

Q+T |

Detection method |

Straight vertical Wave |

|||

|

Instrument model |

HNW-6100 |

Working sensitivity |

Φ4 |

||||

|

Prode model |

2.5P20 |

Coupling way |

Direct contact |

||||

|

Block model |

4340 Alloy Steel Axle Shaft Forging Rough Machined Square Drive Shaft 0 4340 Alloy Steel Axle Shaft Forging Rough Machined Square Drive Shaft 1 Big calm bottom CS-1 |

Couplant |

Machine oil |

||||

|

Sweep |

Deepness way |

Surface compensation |

0db |

||||

|

Standards |

AS 1065 |

Rate as require |

1:1 |

||||

|

Acceptance standard |

Level 1 |

Acceptable class |

≤Φ4 |

||||

|

Test Result |

Item No |

Forging specifications |

Qty |

Defect |

Result |

Note |

|

|

00055928 |

Φ590*1225 |

3 |

None |

Qualified |

/ |

||

|

4340 Alloy Steel Axle Shaft Forging Rough Machined Square Drive Shaft 2

4340 Alloy Steel Axle Shaft Forging Rough Machined Square Drive Shaft 3

|

|||||||

|

Test Result |

1.The above forgings are meet the standard,The result is eligibility |

||||||

|

Nondestructive testing Signature |

Tested by:(UT-II) |

Approved by:(UT-III) |

|||||