INTRODUCE :

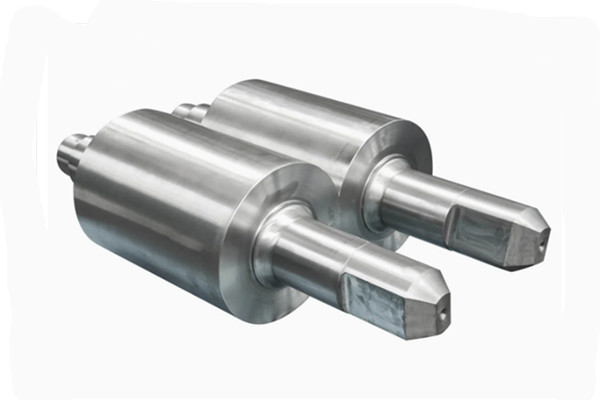

Forged rolls are used in wide cold strip mills including 2-, 4-, 6-high reversing mills, tandem mills, double mills as well as skin pass and temper mills.

With many years of experience, Kingrail Parts can offer a wide range of roll grades to suit a variety of applications, materials and rolling conditions. We offer rolls in electrical steel and electroslag remelted (ESR) qualities. We also offer cold rolling work rolls in high chromium cast iron types.

We also offer services and support for customers with re-hardening and re-cutting.

SPECIFICATIONS :

Materials and properties

The table below outlines our main roll grades, all materials are ESR process.

|

Type |

Main Material |

Hardness |

Hardness Uniformity |

Depth of hardness |

Size |

|

Work Roll |

9Cr2Mo |

85-102 HSD |

3HSD |

8~15mm |

¢200-600mm |

|

MC3 |

85-102HSD |

3HSD |

15-30mm |

¢200-1000mm |

|

|

MC5 |

85-102HSD |

3HSD |

20-40mm |

¢300-1000mm |

Manufacturing process

Product design → Smelting (EF+ESR) → Forging → (Normalizing) → Spheroidizing annealing, hydrogen annealing → Rough turning of roller surface (cutting test blocks) → Inspection (UT, macro, micro, size, appearance) → Warehousing and receiving materials → Rough machining → Ultrasonic flaw detection → Tempering → Hardness inspection → Semi-finishing → Tempering of roller neck surface and thrust end face → Roller neck hardness inspection → Semi-finishing → Ultrasonic flaw detection → Roller surface quenching (+cold treatment+low temperature tempering) → Roller hardness inspection → Finishing → Inspection → Warehousing → Rust-proof packaging → Transportation

Advantages

1. No macro segregation, very little micro segregation.

2. Very few and fine non-metallic inclusions; scattered distribution.

3. Dense and uniform structure.

4. High toughness and strength

5. Helpful in improving the roller's fatigue resistance and thermal shock resistance.

Get more help

Please contact us for more information and quotes.