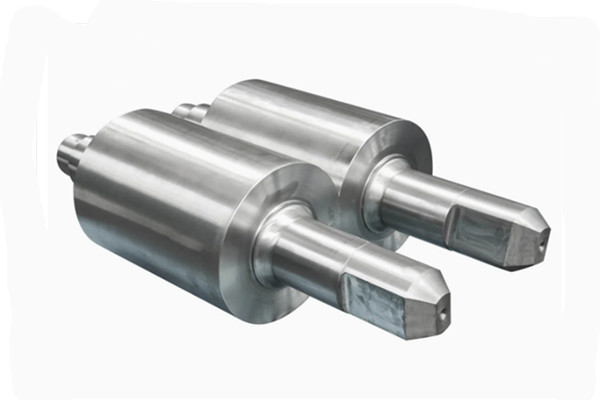

INTRODUCE :

SG iron rolls are available in a variety of hardnesses and compositions for a wide range of applications. These rolls are essentially an infinite chill type material, but with spherical rather than flake graphite, and with higher proportions of nickel, molybdenum and carbon added.

The matrix structure varies from ferrite-pearlite, pearlite to bainite and martensite, with varying carbide contents and spherical/globular graphite.

Applications

1. Roughing stands for bar, wire and section mills;

2. Intermediate stands for bar mills;

3. Sleeves for universal stands.

SPECIFICATIONS :

Chemical Composition

|

MATERIAL |

GRADE |

CHEMISTRY |

BARREL HARDNESS (HSC) |

|||||

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

|||

|

Pearlite (SGP) |

Pearlite I |

2.90-3.60 |

1.40-2.20 |

0.40-1.00 |

0.10-0.60 |

1.50-2.00 |

0.20-0.80 |

45-55 |

|

Pearlite II |

2.90-3.60 |

1.20-2.00 |

0.40-1.00 |

0.20-1.00 |

2.01-2.50 |

0.20-0.80 |

55-65 |

|

|

Pearlite III |

2.90-3.60 |

1.00-2.00 |

0.40-1.00 |

0.20-1.00 |

2.51-3.00 |

0.20-0.80 |

62-72 |

|

Physical Properties

|

TYPICAL PHYSICAL PROPERTIES |

||

|

Neck Hardness (HSC) |

Tensile Strength (N/mm2) |

Unevenness of Barrel Surface Hardness (HSC) |

|

35-55 |

≥350 |

<5 |

Why Choose Us

1. Standardized management makes the coil records well documented and the coil quality can be traced at any time.

2. More than 20 years of manufacturing experience has made our roller research and development in this field more in-depth.

3. The customization of different rollers is the responsibility of the technical team.

4. From raw materials to the final finished coil, we produce it ourselves.

5. We have our own steel mill to test new products, and if the test is successful, we will put it into mass production.

Get More Help

Please contact us for more information and quotes.