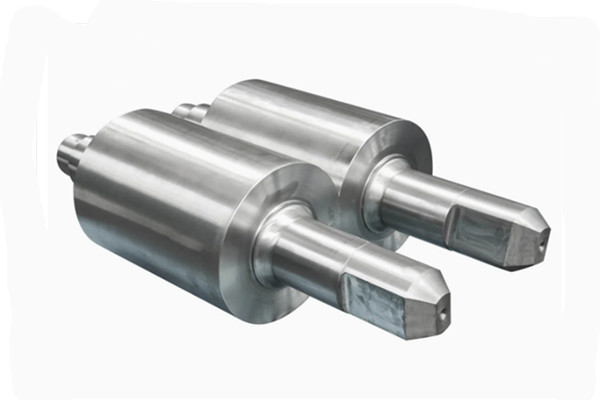

INTRODUCE :

Alloy infinite chilled cast iron rolls are cast iron with fine intergranular graphite evenly distributed in the working layer of the roll body. The size, shape and distribution of graphite and carbides are controlled by the chilling effect and the content of alloying elements. The addition of alloying elements such as manganese, nickel, chromium and molybdenum transforms the matrix structure from pearlite and bainite to martensite. The presence of a small amount of fine graphite improves the roll's resistance to spalling, thermal cracking and wear.

Applications

1. Wire rod finishing.

2. Hot strip rolling and plate mill rolling of flat products.

3. Cold rolling of non-ferrous metal sheets.

SPECIFICATIONS :

Chemical Composition

|

Designation of rolls |

Material code |

C |

Si |

Mn |

Ni |

Cr |

Mo |

|

CrMo indefinite chilled cast iron roll |

IC |

3.1-3.4 |

0.6-0.9 |

0.5-1.0 |

|

0.7-1.1 |

0.2-0.6 |

|

NiCrMo indefinite chilled cast iron roll (Ⅰ) |

IC Ⅰ |

3.1-3.4 |

0.6-0.9 |

0.5-1.0 |

0.6-0.8 |

0.7-1.1 |

0.2-0.6 |

|

NiCrMo indefinite chilled cast iron roll (Ⅱ) |

IC Ⅱ |

3.1-3.4 |

0.6-1.0 |

0.5-1.0 |

2.2-2.8 |

0.7-1.1 |

0.2-0.6 |

|

NiCrMo indefinite chilled cast iron roll (Ⅲ) |

IC Ⅲ |

3.1-3.4 |

0.6-1.0 |

0.5-1.0 |

2.2-2.8 |

0.8-1.3 |

0.2-1.0 |

|

NiCrMo indefinite chilled cast iron roll (Ⅳ) |

IC Ⅳ |

3.1-3.4 |

0.6-1.0 |

0.5-1.0 |

3.1-4.3 |

1.0-1.3 |

0.2-1.0 |

|

NiCrMo indefinite chilled cast iron roll (Ⅴ) |

IC Ⅴ |

3.1-3.4 |

0.8-1.2 |

0.5-1.0 |

3.8-4.5 |

1.4-2.0 |

0.2-1.2 |

Physical Properties

|

Designation of rolls |

Material code |

Barrel hardness |

Neck hardness |

Tensile strength |

|

CrMo indefinite chilled cast iron roll |

IC |

50-70 |

35-55 |

>160 |

|

NiCrMo indefinite chilled cast iron roll (Ⅰ) |

IC Ⅰ |

55-72 |

35-55 |

>160 |

|

NiCrMo indefinite chilled cast iron roll (Ⅱ) |

IC Ⅱ |

55-72 |

35-55 |

>160 |

|

NiCrMo indefinite chilled cast iron roll (Ⅲ) |

IC Ⅲ |

65-78 |

35-55 |

>350 |

|

NiCrMo indefinite chilled cast iron roll (Ⅳ) |

IC Ⅳ |

70-83 |

35-55 |

>350 |

|

NiCrMo indefinite chilled cast iron roll (Ⅴ) |

IC Ⅴ |

77-82 |

35-55 |

>350 |

Why Choose Us

1. Standardized management makes the coil records well documented and the coil quality can be traced at any time.

2. More than 20 years of manufacturing experience has made our roller research and development in this field more in-depth.

3. The customization of different rollers is the responsibility of the technical team.

4. From raw materials to the final finished coil, we produce it ourselves.

5. We have our own steel mill to test new products, and if the test is successful, we will put it into mass production.

Get More Help

Please contact us for more information and quotes.