INTRODUCE :

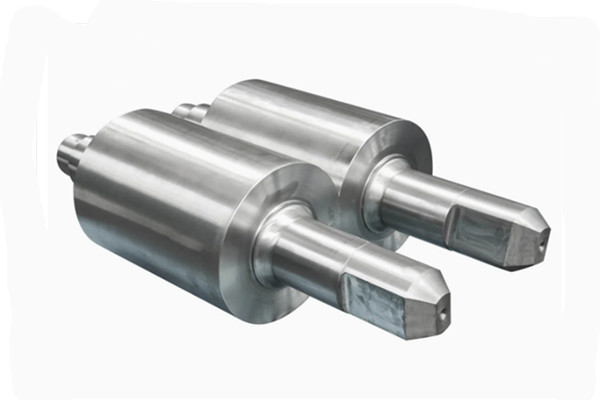

Adamite rolls, also known as semi-steel rolls, are mill rolls made of a material that combines the characteristics of cast iron and steel.

Kingrail Parts can produce adamite rolls of various sizes and specifications. Our adamite rolls can be used in various industrial fields, especially in the metal processing industry.

Features

1. There is almost no hardness gradient in the working layer

2. Excellent fire crack resistance

3. Good wear resistance and toughness

Applications of adamite rolls

* Hot-rolled strip steel,

* Bar finishing mill;

* Universal rolling mill for steel sections;

* High-speed wire rod pre-finishing mill

* Roughing mill working rolls;

* Chilled strip steel working rolls,

* Middle Roller

SPECIFICATIONS :

Size Limit

Maximum: 600mm diameter

Minimum: 150mm diameter

Chemical Composition%

|

National Standards |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

V |

W |

|

Code No. |

||||||||||

|

AD140I |

1.3-1.5 |

0.3-0.6 |

0.7-1.1 |

≤0.035 |

≤0.030 |

0.8-1.2 |

0.5-1.2 |

0.2-0.6 |

- |

- |

Physical Properties

|

Physical Property |

Application |

||

|

Code No. |

Roll Barrel Hardness(HSD) |

Roll Neck Hardness(HSD) |

|

|

AD140I |

35-45;40-50 |

≤45 |

Roughing and intermediate stands of wire and bar, small and medium-sized section steel; seamless steel pipe roughing mills; backup rolls for strip steel, edger rolls. |

Why Choose Us

1. Standardized management makes the coil records well documented and the coil quality can be traced at any time.

2. More than 20 years of manufacturing experience has made our roller research and development in this field more in-depth.

3. The customization of different rollers is the responsibility of the technical team.

4. From raw materials to the final finished coil, we produce it ourselves.

5. We have our own steel mill to test new products, and if the test is successful, we will put it into mass production.

Get more help

Please contact us for more information and quotes.