INTRODUCE :

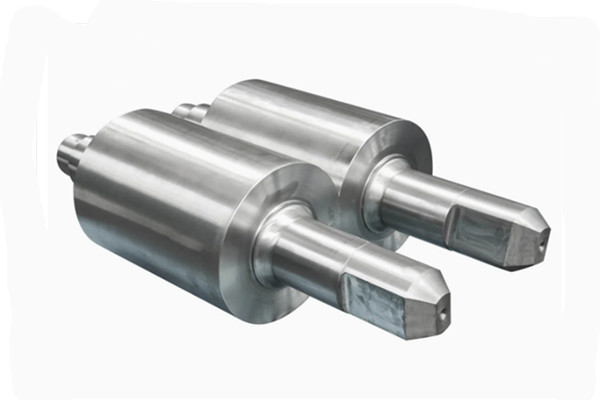

As a professional rolling mill roll manufacturer in China, Kingrail Parts can produce various metallurgical rolls for various types of steel, bars, high-speed wire, strip, hot and cold strip mills.

With 20 years of production experience, we can provide customized services and customized products according to different working conditions of the rolling mill.

SPECIFICATIONS :

Our products

1. Back-up Rolls

2. Work rolls

3. Strip rough mill and plate mill

4. Cold rolling strip rolls

Conventional rolls

1. Alloy chilled cast iron rolls

2. Alloy infinite chilled cast iron rolls

3. Alloy SG iron rolls

4. Duplex spun-cast\Duplex static-cast rolls

5. Alloy cast steel rolls

6. Adam rolls

7. Graphite steel rolls

Casting roll manufacturing process

Molding → smelting → centrifugal casting → cleaning → preliminary heat treatment → rough machining → differential heat treatment → finishing → packaging and delivery.

Forged steel roller manufacturing process

Arc furnace smelting → LF\VD refining → ingot casting → annealing → cleaning → electroslag remelting → annealing → forging → post-forging heat treatment → rough machining → preparatory heat treatment → semi-finishing → double-frequency quenching or differential temperature treatment → cryogenic treatment → tempering → finishing → packaging and delivery.

Our market

After 20 years of production. The mill rollers we produce have been exported to more than 30 countries and regions. Such as: UAE, Egypt, Russia, Luxembourg, Turkey, Spain, India, etc.

Our services

1. Inquiry and consulting support.

2. Planning layout and design require machinery.

3. Welcome to visit our factory.

4. During the production process and before leaving the factory, all performance indicators are strictly tested and controlled by a professional QC team according to the process.

5. Track quality throughout the process and guide installation and use throughout the process.

Get more help

Please contact us for more information and quotes.