INTRODUCE :

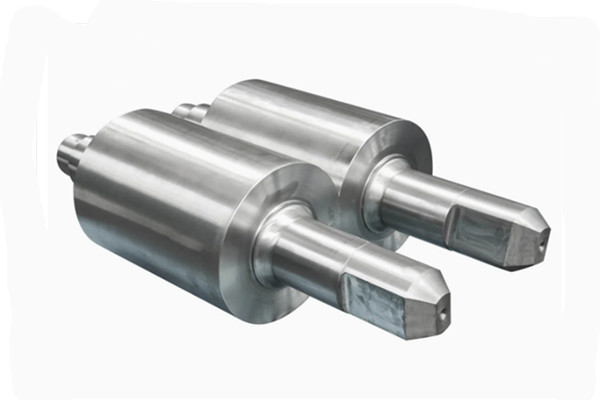

Backup rolls are generally used in tension straighteners, levelers, rolling mills and other equipment. As a professional manufacturer from China, Kingrail Parts can provide you with a full range of forged and cast solid steel backup rolls to meet various applications and needs in the market.

Our backup rolls are available in a variety of grades to meet different hardness and wear resistance requirements. We can also produce custom rolls for special purposes.

SPECIFICATIONS :

Manufacturing Capacity

Total length: 6000mm - 6500mm

Body length: 3500mm - 2500mm

Diameter: 910mm - 1500mm

Hardening depth (single side): 50mm - 100mm

Maximum weight: 13000kg - 50000kg

Capacity (tons/year): 8000 - 1000

Chemical composition

|

Material |

Chemical Composition |

||||||||

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

V |

P |

S |

|

|

3%Cr Series |

0.4-0.8 |

0.3-0.7 |

0.4-0.8 |

4.5-5.5 |

0.2-0.8 |

0.3-0.8 |

<0.25 |

≤0.015 |

≤0.015 |

|

5%Cr Series |

0.4-0.65 |

0.2-0.6 |

0.4-0.8 |

2.0-3.0 |

0.2-0.8 |

0.3-0.7 |

<0.25 |

≤0.015 |

≤0.015 |

Chemical properties

|

Material |

Tensile Property Mpa |

Barrel Hardness HSD |

Working Layer Composition |

Hardening Depth mm |

Roller Application |

|

3%Cr Series |

≥880 |

50-65 |

Martensite (bainite) + Carbide |

40-60 |

Single stand mill, Cold & Hot rolling tandem mill |

|

5%Cr Series |

≥950 |

55-80 |

Martensite (bainite) + Carbide |

50-100 |

Single stand mill, Cold & Hot rolling tandem mill |

Production process

Roller blank manufacturing → Roller blank acceptance → Annealing → Rough turning → Ultrasonic flaw detection → High temperature quenching → Low temperature tempering → Ultrasonic flaw detection → Finishing → Ultrasonic flaw detection → Grinding roller body → Rolling number → Inspection → Cleaning → Packing → Shipping

Get more help

Please contact us for more information and free quotes.